Precision has become the foundation of modern manufacturing. In industries such as aerospace, automotive, medical equipment production and many others, even the slightest deviation in material thickness can affect product reliability and safety. X-ray thickness gauging has emerged as a critical technology for ensuring accuracy in these high-stakes environments. By using controlled X-ray radiation to measure material density and thickness, it allows manufacturers to verify quality without altering or damaging the product.

X-ray thickness gauging operates on a simple but powerful principle. When X-rays pass through a material, part of the radiation is absorbed while the rest is transmitted. The amount absorbed depends on the material’s thickness and density. By analysing this absorption, the system calculates precise measurements in real time.

The technology’s non-destructive nature makes it invaluable in sectors where precision and consistency determine performance. In the medical equipment industry, X-ray gauging ensures that implants and surgical devices meet strict dimensional standards, reducing the risk of failure during use. In aerospace and defence manufacturing, it verifies the uniformity of critical structures, where any flaw could compromise safety. The automotive sector uses it to monitor coatings and brake components, maintaining both strength and performance. In electronics, it measures film and circuit thicknesses essential to device functionality.

One of the key strengths of X-ray thickness gauging lies in its ability to deliver accurate, repeatable measurements across a range of materials, metals, plastics, composites, and thin films. In addition to traditional transmission-based methods, X-ray fluorescence (XRF) techniques are also employed, particularly for coating thickness measurements, by analyzing the secondary X-rays emitted from a material’s surface. Together, these approaches enable consistent assessments that ensure uniformity and reliability across manufacturing processes. The technology is fast, adaptable to automation, and capable of detecting inconsistencies that traditional tools often miss, making it ideal for continuous quality monitoring without disrupting production flow.

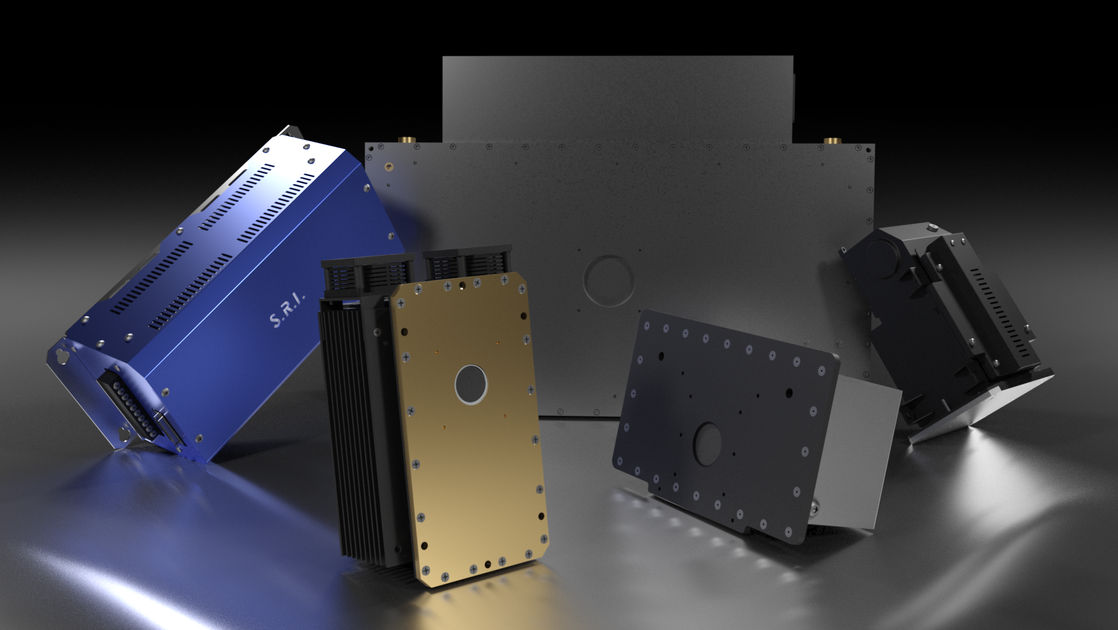

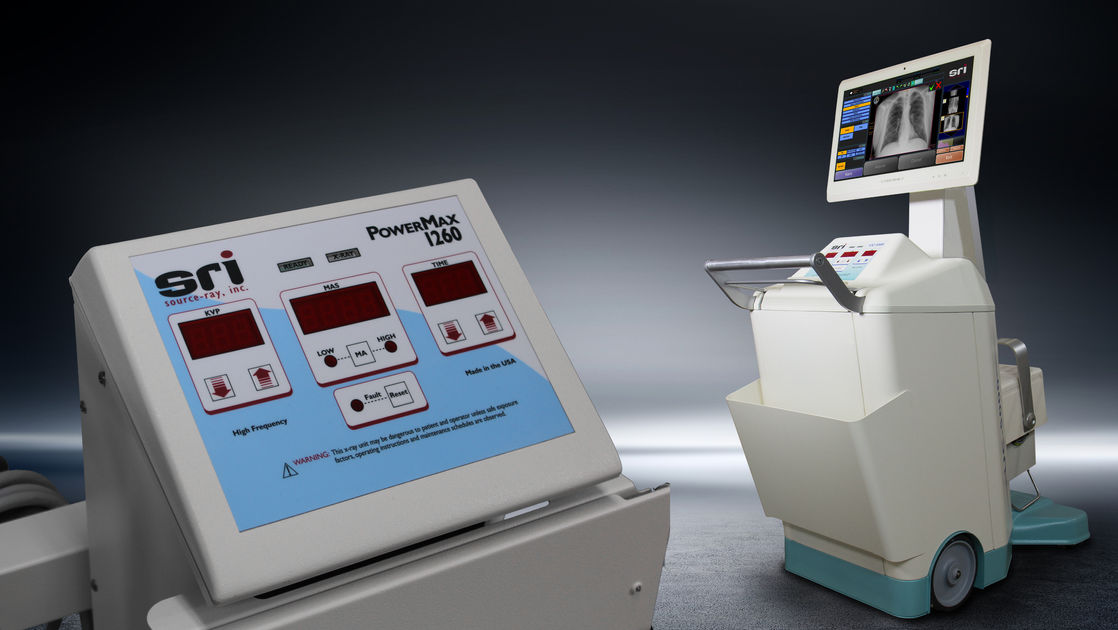

The performance of any X-ray thickness gauging system depends heavily on the stability and accuracy of the X-ray generator. A consistent beam output ensures uniform results across production runs, while advanced control systems maintain steady voltage and current for dependable operation. Modern generators are engineered to provide long service life, minimal maintenance, and precise radiation delivery, all essential for industrial environments that demand continuous reliability.

In conclusion, X-ray thickness gauging stands as a cornerstone of modern quality assurance. Source-Ray offers a variety of standard and custom-made x-ray generators, so that companies can perform efficient, reliable thickness measurements setting new benchmarks for safety and precision across sectors. As innovation advances, these systems will remain essential tools for safeguarding both performance and safety across the industrial landscape.