In industries where safety, reliability, and precision are critical, non-destructive testing (NDT) plays a vital role in ensuring structural integrity without altering the materials being inspected. Among the range of NDT techniques, industrial X-ray inspection stands out as one of the most versatile and effective methods for detecting internal defects and ensuring product quality.

Modern industrial X-ray generators provide controlled, high-energy radiation capable of penetrating metals, composites, and other dense materials. By exploiting the differential attenuation of X-rays, these systems reveal flaws invisible to the naked eye, enabling early defect detection, reducing operational risk, and maintaining compliance with stringent industry standards. Beyond industrial components, X-ray inspection is also applied in agriculture and food industries, helping analyse seeds and detect internal inconsistencies without damaging the product.

Why X-Ray Generators Are Essential in NDT

Unlike surface inspection methods, X-ray NDT allows inspectors to visualize internal structures in materials such as steel, aluminum, composites, and castings. The X-ray generator delivers stable, precise radiation output, which is crucial for generating high-resolution images with consistent contrast and reliable detection of defects.

X-ray inspection relies on attenuation differences as X-rays pass through materials of varying density and thickness. These differences create radiographic contrast, which allows for the identification of:

Porosity, voids, and inclusions

Internal cracks and lack of fusion

Density variations

Misalignments and dimensional deviations

A reliable X-ray generator ensures uniform exposure, predictable penetration depth, and repeatable image quality in both laboratory and field environments. Without this consistency, defect detection may become unreliable, increasing the risk of missed flaws or false positives.

Key Industrial Applications of X-Ray NDT

Industrial X-ray generators are deployed across a wide spectrum of industries:

1. Weld Inspection

In oil and gas, power generation and construction, weld integrity is critical. X-ray inspection detects porosity, cracks, lack of fusion, and inclusions, helping prevent leaks and catastrophic failures.

2. Aerospace and Aviation

Aircraft components demand the highest inspection standards. X-ray NDT examines turbine blades, composite structures, and critical assemblies to ensure compliance with strict safety and performance requirements.

3. Casting and Manufacturing Quality Control

Foundries and manufacturers use X-ray inspection to detect internal voids, shrinkage, and inconsistencies in cast or molded parts, reducing scrap and improving production efficiency.

4. Pipeline and Infrastructure Inspection

Pipelines, pressure vessels, and structural components are evaluated to identify corrosion, wall thinning, and internal damage, even in remote or challenging environments.

5. Electronics and Automotive Components

From circuit boards to safety-critical automotive parts, X-ray NDT verifies internal connections, solder joints, and hidden assemblies without dismantling the product.

X-Ray Energy and Power Considerations Across Industries

Different materials and applications require varying X-ray energy (kV) and power (W) levels. Our generators operate efficiently in medium-energy ranges while scalable higher-energy systems are available for thicker or denser components.

*Energy and power ranges are typical; actual requirements depend on material thickness, density, and inspection objectives. Our generators reliably handle most of these applications.

Benefits of Industrial X-Ray NDT Systems

Non-destructive internal inspection for defect detection

Enhanced QA/QC and improved product reliability

Scalable inspection solutions adaptable across industries

Consistent, repeatable imaging for diverse materials and components

By combining adjustable energy, reliable power stability, and digital radiography integration, X-ray NDT systems provide high-resolution imaging for defect detection, quality assurance, and compliance.

Technical FAQ

What types of defects can X-ray NDT detect?

Porosity, voids, inclusions, internal cracks, misalignment, and density variations can all be detected non-destructively.

How does digital radiography improve inspection?

Digital systems enable faster image acquisition, enhanced contrast, traceable results, and efficient review and archival.

Why is adjustable energy and power output important?

Flexibility in energy (kV) and power (W) ensures precise imaging across materials of varying thickness and density, enabling reliable defect detection in all applications.

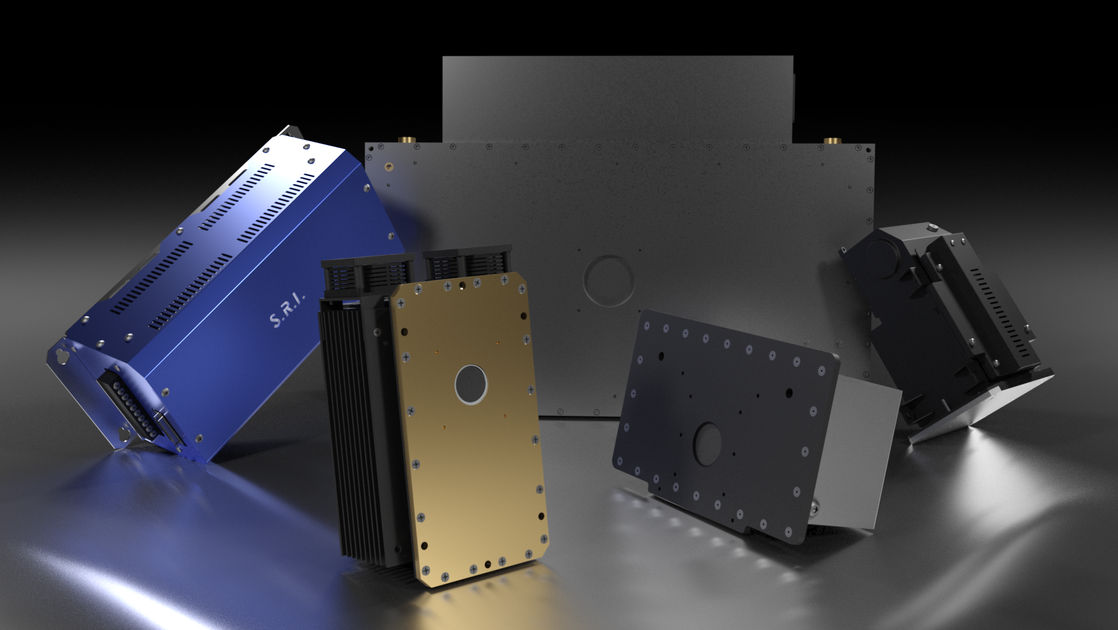

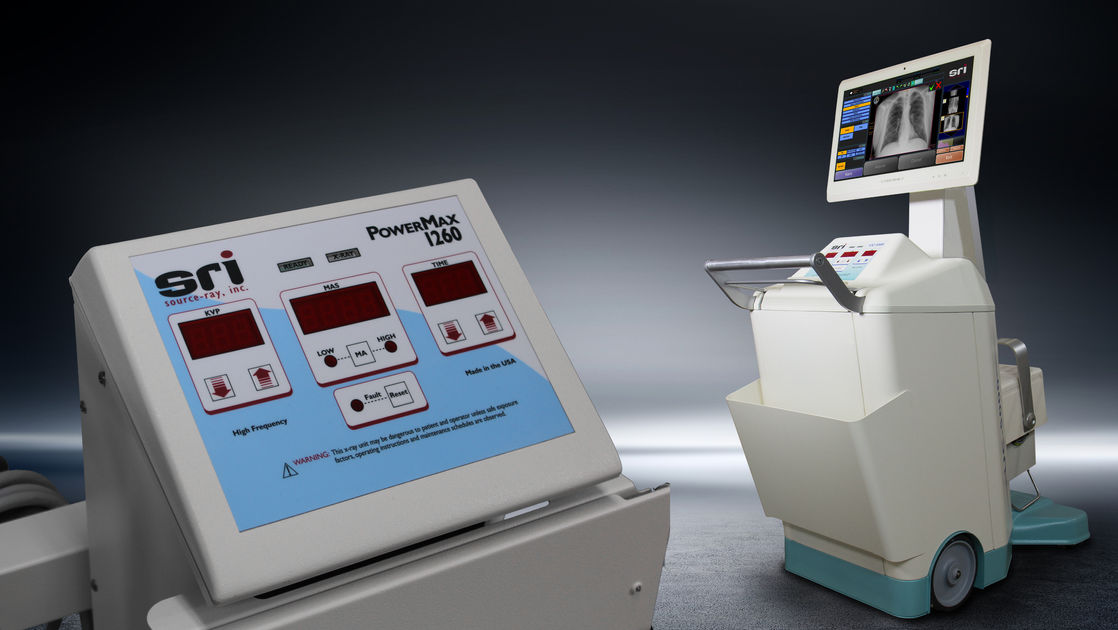

Engineering X-Ray Generators for Real-World Demands

Industrial NDT environments are often harsh. X-ray generators must perform consistently under variable power conditions, temperature fluctuations, vibration, and extended duty cycles. Thoughtful engineering ensures stability, precision, and long-term reliability, which are essential for accurate and repeatable inspections.

Source-Ray designs and engineers industrial X-ray generators in the United States specifically for NDT applications. Each system prioritizes robust design, accurate control, and field-ready performance, supporting professionals in laboratories, factories, and on-site inspection environments.