X-ray generators play a crucial role across various industries, providing essential non-destructive evaluation (NDE) solutions. High voltage X-ray generators enable detailed internal examination without damaging or altering components, improving quality control, safety, and efficiency. Below, we explore how X-ray generators are utilized in key industrial applications.

1. Non-Destructive Testing (NDT)

Non-destructive testing is essential for evaluating the structural integrity of materials without causing damage, particularly in industrial applications. X-ray generators allow professionals to detect internal flaws such as cracks, voids, or inclusions, ensuring safety and compliance with industry standards. High-resolution imaging is critical for accurate diagnostics and evaluation in sectors like oil & gas, aerospace, and automotive. (Image Source)

Credit & Source: National Air & Space Museum

2. PCB & Battery Inspection

PCB Inspection

In electronics manufacturing, ensuring the quality of printed circuit boards (PCBs) is critical. X-ray generators enable detailed visualization of solder joints, component alignment, and internal circuitry, identifying defects such as bridging, solder voids, or misplaced components. Micro-focus X-ray generators provide the high-resolution imaging required to inspect increasingly compact and densely populated PCBs. Industrial X-ray generators are favored globally for their precision, reliability, and ability to detect the smallest imperfections in PCB inspection.

Battery Inspection

X-ray technology is essential for inspecting lithium-ion batteries used in electric vehicles, electronics, and aerospace. It allows manufacturers to non-destructively examine internal structures, identifying defects like misaligned electrodes, cracks, voids, or foreign materials. This ensures product safety and performance while preventing risks such as overheating or failure. High-resolution X-ray imaging, often using CT, helps detect issues early in the production process, making it a vital tool in quality control and maintaining high manufacturing standards.

3. X-ray Diffraction/Refraction

X-ray diffraction and refraction are essential, complementary techniques in materials science. Diffraction involves analyzing crystalline structures by measuring the angles and intensities of X-rays scattered from atomic lattices, which helps identify phases, assess crystallinity, and measure residual stresses. In contrast, X-ray refraction, including phase-contrast imaging, detects subtle density variations, revealing internal defects like micro-cracks and voids that traditional imaging might miss, thus providing critical insights into a material’s internal integrity. Industrial X-ray generators facilitate these detailed analyses, supporting research and quality control in pharmaceuticals, metallurgy, and advanced materials (Source)

4. Thickness Gauging

Thickness gauging using X-ray generators provides precise, non-contact measurements of sheets and slabs made from materials such as steel, copper, and aluminum, critical for quality assurance and regulatory compliance. In addition to traditional transmission-based methods, X-ray fluorescence (XRF) techniques are also employed, particularly for coating thickness measurements, by analyzing the secondary X-rays emitted from a material’s surface. Together, these approaches enable accurate, repeatable assessments that ensure uniformity and reliability across metal manufacturing processes worldwide.

5. Irradiation

X-ray irradiation is used in industrial processes such as sterilization, material modification, and curing. Applications include medical device sterilization, polymer cross-linking, and certain agricultural treatments. Industrial X-ray generators provide controlled, precise doses of radiation, enhancing process efficiency, scalability, and safety, especially where alternatives like gamma or electron beams are less suitable.

6. Component Counting

Industrial X-ray generators efficiently automate component counting processes, significantly reducing manual labor and error rates. By precisely counting components within sealed packages or reels, these systems improve inventory management accuracy, operational efficiency, and productivity.

7. Food Inspection

Ensuring food safety and quality is paramount. X-ray generators detect foreign objects such as bone or metal fragments, glass, or stones in packaged foods, meats, and produce. This process significantly reduces contamination risks and product recalls. Industrial X-ray inspection systems help maintain stringent food safety standards internationally.

8. Fill Height Inspection in Bottling

Industrial X-ray generators measure fill height in bottles and containers with high accuracy, helping manufacturers maintain consistent product levels to meet industry standards. By detecting deviations in real time, X-ray inspection minimizes waste, prevents costly errors, and enhances overall production efficiency and consumer trust.

9. Industrial Computed Tomography (CT)

Industrial computed tomography utilizes X-ray generators to produce detailed 3D images of objects, allowing comprehensive internal assessments. This application is critical in analyzing complex assemblies, reverse engineering, and defect analysis. X-ray generators enable advanced, high-resolution industrial CT applications.

10. Security Screening

Industrial X-ray generators help enhance safety, providing a safer environment for screening applications. They are a valuable tool for improving safety in numerous applications. From airport and border security to industrial screening, X-ray generators aid in detecting weapons, explosives, smuggled goods, and hazardous materials, ensuring a safer environment for all.

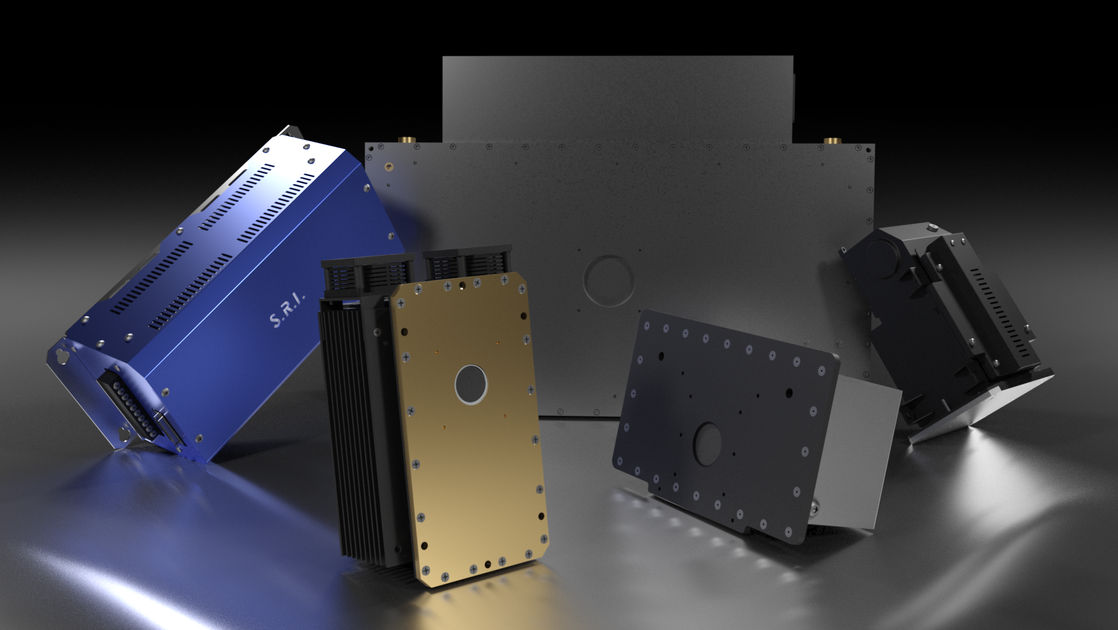

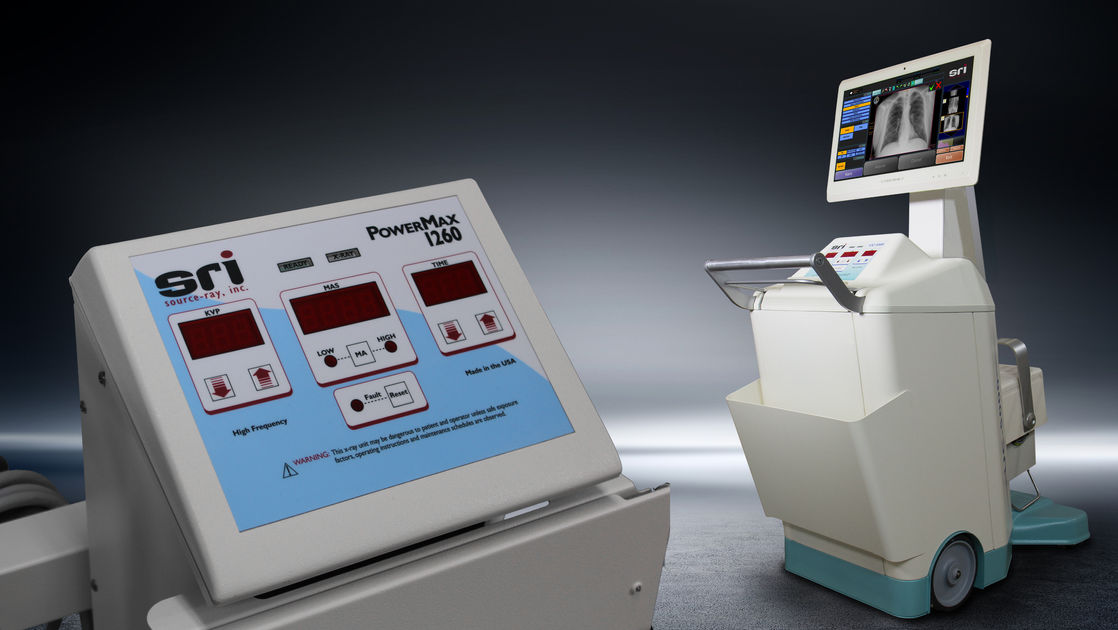

Source-Ray X-ray Generators for Industrial Applications

Globally trusted, Source-Ray's modular & fully integrated X-ray generators offer unparalleled reliability, precision, and adaptability across diverse industrial applications. Designed, developed, and engineered in the United States, their robust design, ease of integration, and consistent performance make them the ideal choice for industrial inspection and analysis needs worldwide.